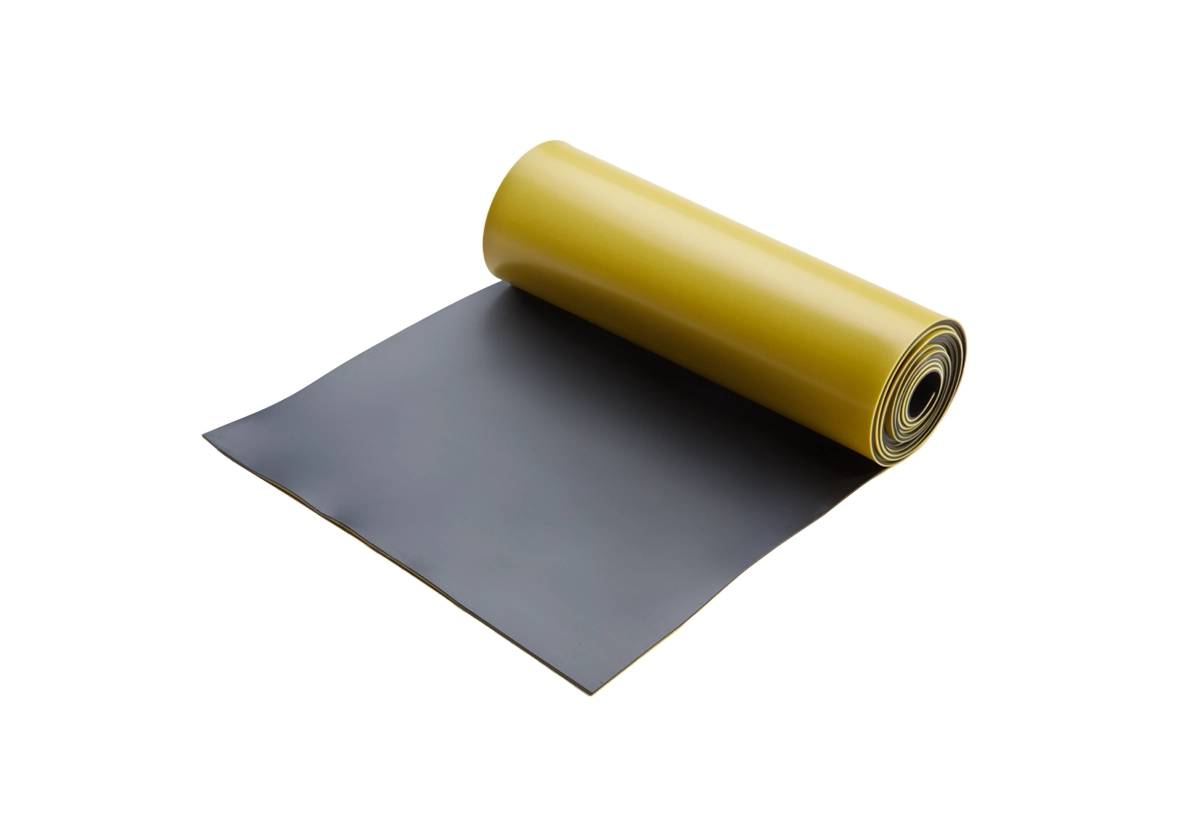

PVC Geomembranes have a wide range of applications. Their durability is enhanced for specific uses by adding various additives to their formulas. Generally, they are highly resistant to plant roots, can withstand heating and cooling cycles, are flame-retardant, long-lasting, impact-resistant, and have high tensile properties. They remain flexible in cold temperatures. PVC Geomembranes can be produced in desired colors and sizes. Their field installation is easy. They are effortlessly joined using robots that perform standard double-channel stitching.

General Description

General Description

Can be produced in various colors and sizes.

Can be produced in various colors and sizes. Minimally affected by vibrations in structures due to the free laying technique.

Minimally affected by vibrations in structures due to the free laying technique. Joints are fused using the fusion welding system.

Joints are fused using the fusion welding system. Can be made UV resistant, antibacterial, signal layered, and geotextile reinforced upon request.

Can be made UV resistant, antibacterial, signal layered, and geotextile reinforced upon request. Remains flexible in cold temperatures, does not crack or break.

Remains flexible in cold temperatures, does not crack or break. High tensile and elongation strength.

High tensile and elongation strength. Highly resistant to mechanical impacts.

Highly resistant to mechanical impacts. Long-lasting (minimum 40 years).

Long-lasting (minimum 40 years). Classified as Class E in fire resistance; does not catch fire.

Classified as Class E in fire resistance; does not catch fire. Prevents corrosion and is resistant to aging.

Prevents corrosion and is resistant to aging. Joints are fused using robots that perform double-channel stitching.

Joints are fused using robots that perform double-channel stitching. Resistant to temperatures ranging from -40 to +70 degrees Celsius.

Resistant to temperatures ranging from -40 to +70 degrees Celsius. Recyclable and reusable.

Recyclable and reusable. Resistant to plant roots.

Resistant to plant roots.