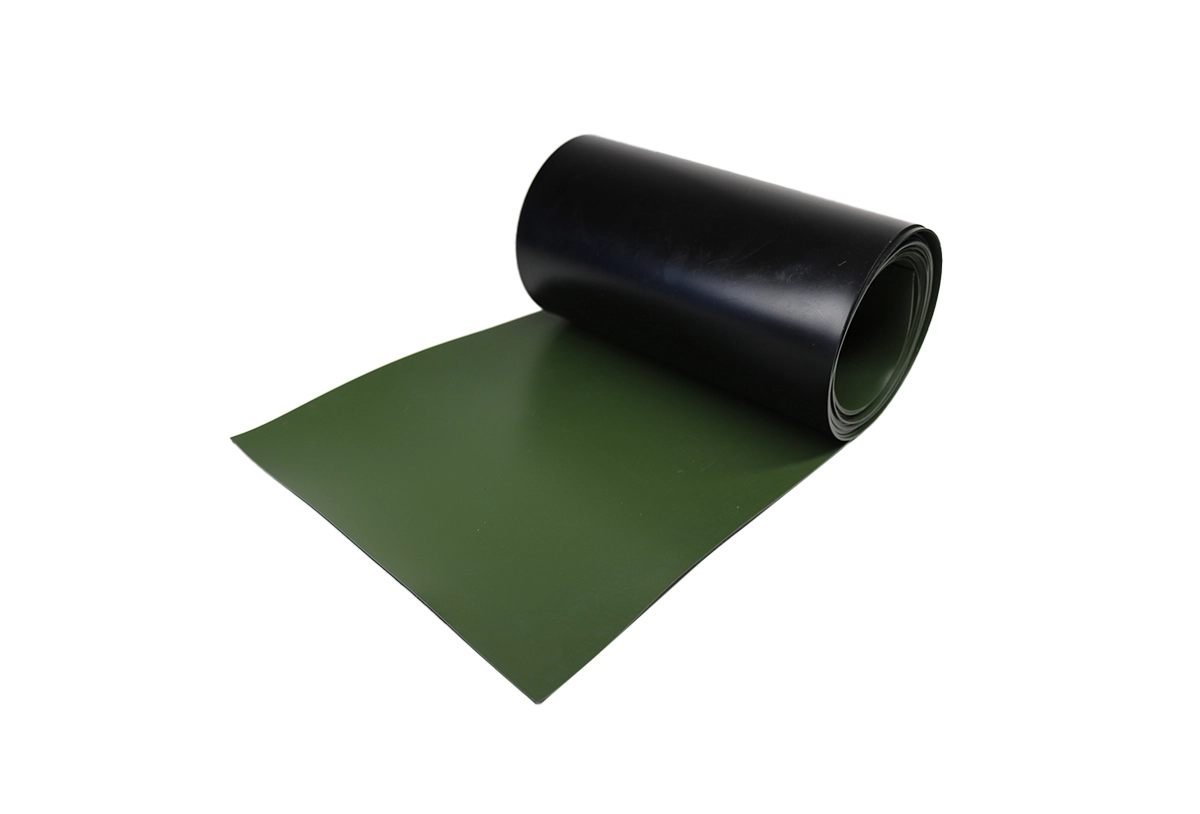

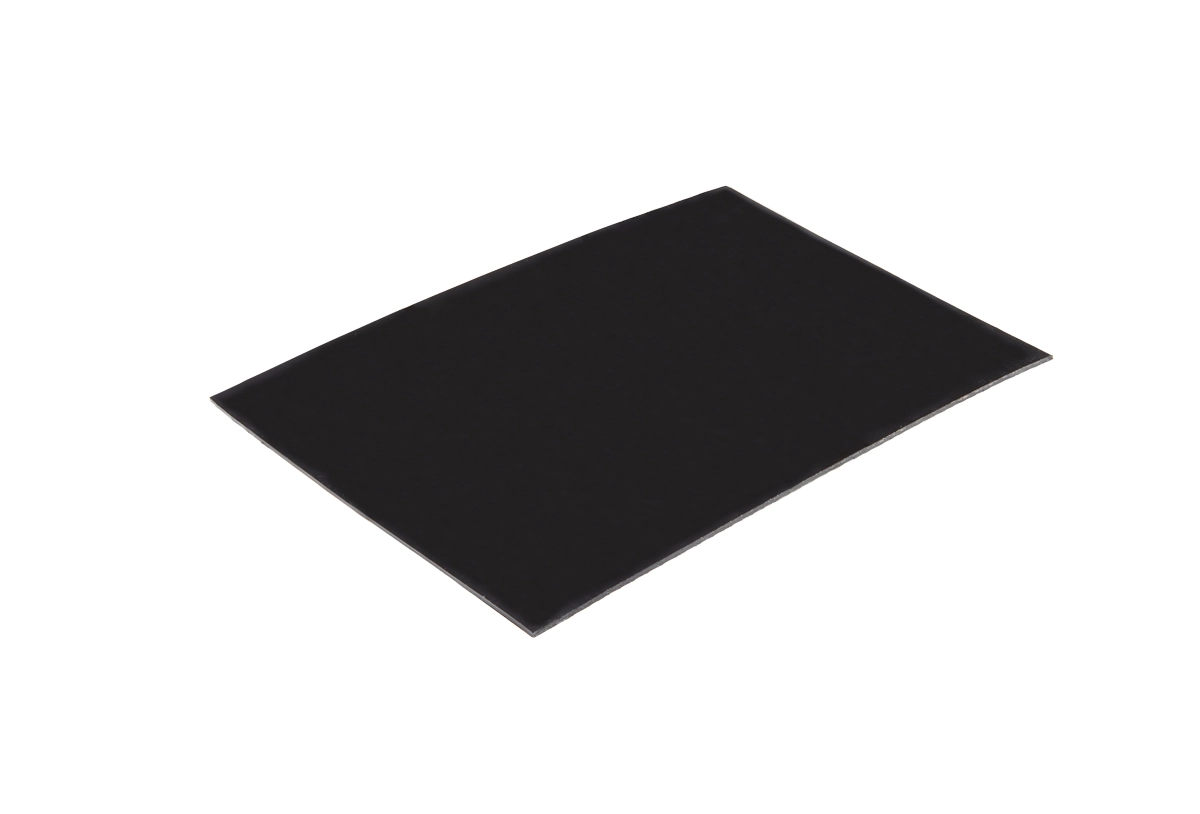

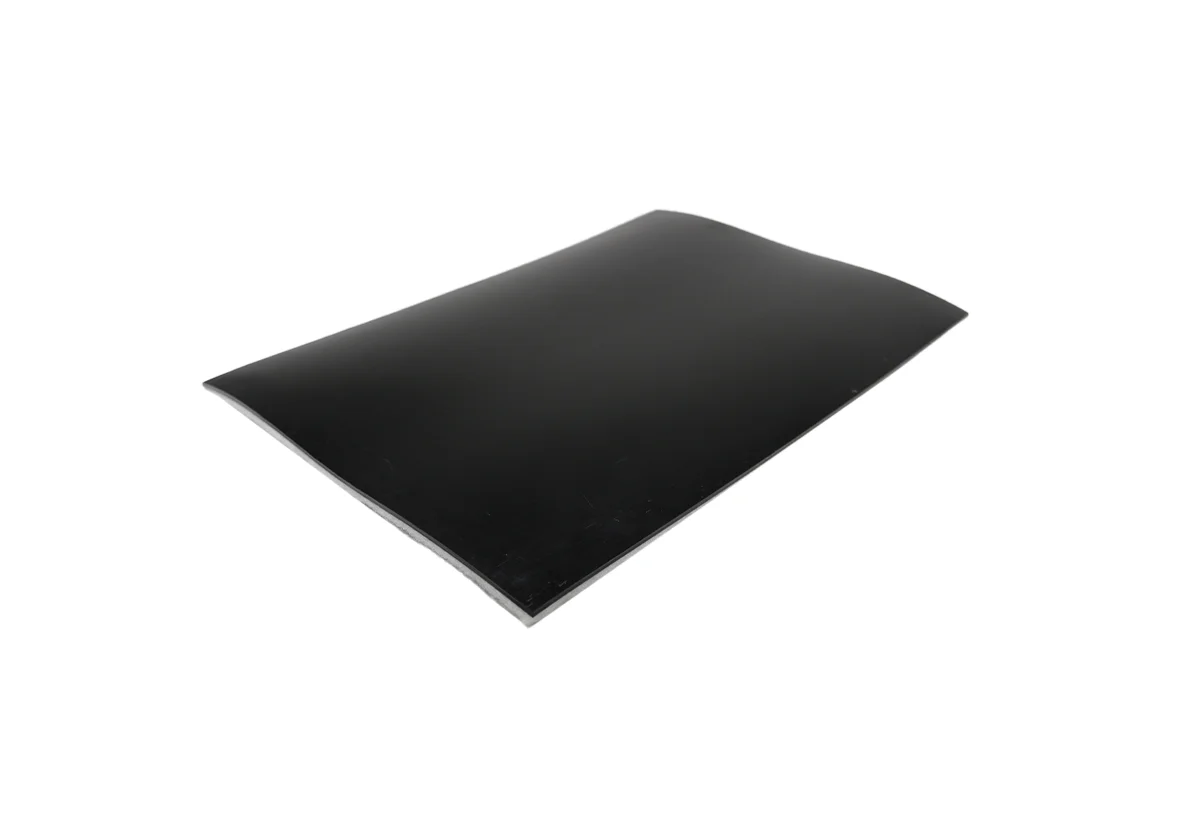

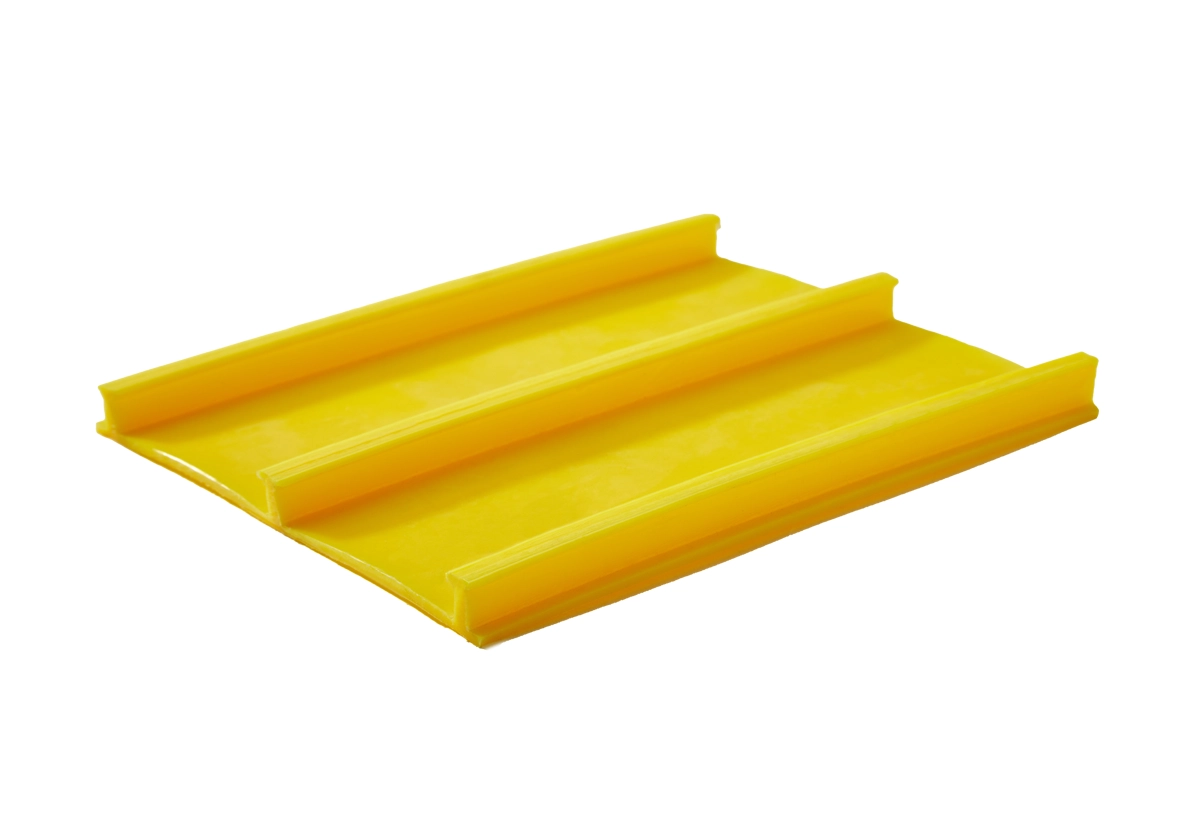

Polyethylene geomembranes are classified according to their densities. High-Density Polyethylene (HDPE) is commonly used. There are also varieties such as Low-Density Polyethylene (LDPE), Linear Low-Density Polyethylene (LLDPE), Very Low-Density Polyethylene (VLDPE), and Medium-Density Polyethylene (MDPE). They stand out for their resistance to chemicals, UV durability, resistance to both organic and inorganic solvents, and resilience against punctures and cracks. They are unaffected by hot-cold cycles and are easily applicable in the field.

General Description

General Description

Highly resistant to chemicals.

Highly resistant to chemicals. UV resistant.

UV resistant. Very high tensile strength.

Very high tensile strength. Low permeability.

Low permeability. Extremely durable against punctures and cracks.

Extremely durable against punctures and cracks. Provides superior protection against leaks.

Provides superior protection against leaks. Resistant to natural conditions.

Resistant to natural conditions. Shows high resistance to organic and inorganic solvents.

Shows high resistance to organic and inorganic solvents. Easily applicable to any kind of terrain.

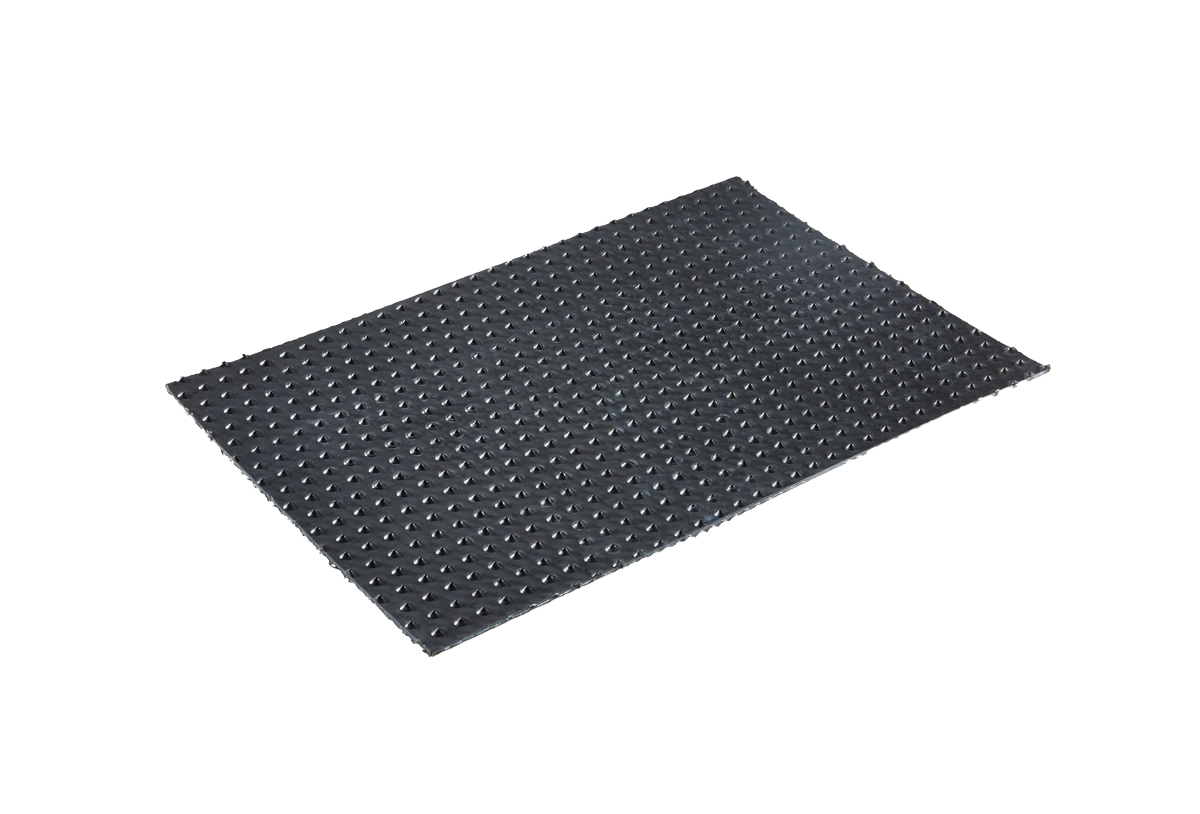

Easily applicable to any kind of terrain. Can be made with Geotextile reinforcement upon request.

Can be made with Geotextile reinforcement upon request. Recyclable and reusable.

Recyclable and reusable.